EPS, XPS, EPE Re-Pelletizing Machines

Re-pelletizing machine for in-house foam or plastic waste recycled

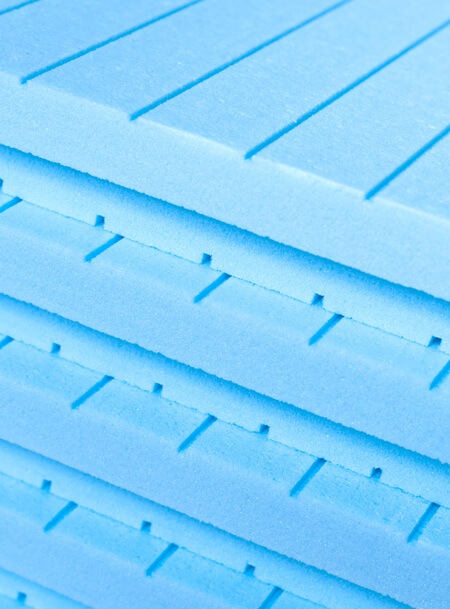

- Material: EPS, XPS, EPE EPP

- Granular Size: 3-5 mm

- Output: 100-600 kg/hr (details see specification)

Features

Sunwell offers an innovative range of die face cut, water flushed type reclaim lines for foam re-pelletizing applications. The process starts with scrap fluff fed into the hopper by an air-vey system, inclusive of a reverse jet fabric filter. The hopper tank includes a rotating blade to avoid bridging to insure flow into a force feeder system. The forced feed system ensures a functional and homogeneous flow of material from the hopper to the feeding connector with internal grooves.

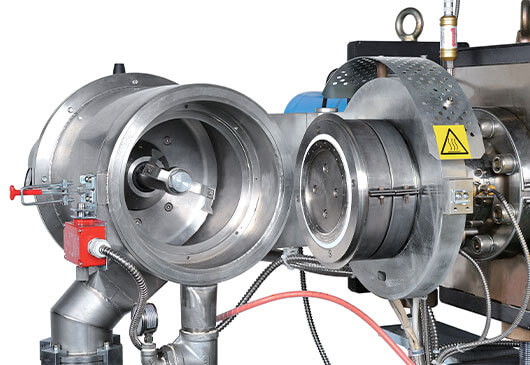

The screw design has a large diameter feed zone to provide the surface area and residence time for gradual plasticizing and a fully homogenized melt. It also can handle a large capacity with a low power requirement. The extruder is equipped with degassing system to purify the melt of volatile contaminants, which avoids the air bubbles, as well as gives a constant flow of material from extruder to the cutting die. The screen changer provides continuous polymer flow and consistent, repeatable process parameters during screen changes to purify the granules. The die cutter, extruder and forced feeder speed can be perfectly synchronized to make the process stable and operation friendly. The die face cutter is horizontally mounted on extruder, which includes an adjustable dial gauge ring to set the blade gap to die face plate properly. Fine tuning the pressure adjustment maximizes the blades working life.

The side hinge open water drum is equipped with tangential cooling water injection ports to cool and flush the granules to dehydrator or vibrator then to the cyclone collector. Available in 3mm to 6mm granule size with low moisture and uniform shape, which are fundamental for the productivity and quality of the end product.

Applications

Specifications

| MODEL | DRC85 | DRC100 | DRC120 |

|---|---|---|---|

|

Material

|

EPS; XPS; EPE

|

EPS; XPS; EPE

|

EPS; XPS; EPE

|

|

Material feed

|

Side Force Feed

|

Side Force Feed

|

Side Force Feed

|

|

Screw Dia. (mm)

|

85

|

100

|

120

|

|

Extruder Type

|

Conical Single

|

Conical Single

|

Conical Single

|

|

Output (kg/h)

|

100 ~200

|

200 ~ 300

|

500 ~ 600

|

|

Granular size (mm)

|

3~5

|

3~5

|

3~5

|

|

Moisture

|

3% Less

|

3% Less

|

3% Less

|

|

Degassing

|

By Vacuum

|

By Vacuum

|

By Vacuum

|

|

L/D

|

34/1

|

34/1

|

34/1

|

|

Cutting type

|

Die Face Cut, Water Flush

|

Die Face Cut, Water Flush

|

Die Face Cut, Water Flush

|

|

Die type

|

Horizontal (Melt Flow Direction)

|

Horizontal (Melt Flow Direction)

|

Horizontal (Melt Flow Direction)

|

|

Drive System

|

SIEMENS AC Drive with FLENDER Gearbox

|

SIEMENS AC Drive with FLENDER Gearbox

|

SIEMENS AC Drive with FLENDER Gearbox

|

|

Space requirement

|

10(L) x 2.5(W) x 4(H)

|

11(L) x 2.5(W) x 5(H)

|

12(L) x 2.5(W) x 6(H)

|