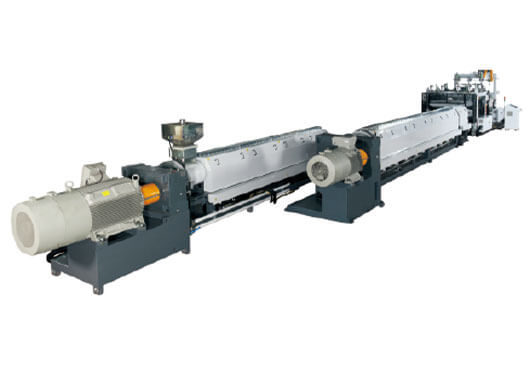

Foam Insulation Board Extrusion (XPS Extrusion) Lines

Foam board extrusion line for building insulation construction.

- Material: GPPS

- Material Thickness: 20-200 mm (details see specification)

- Output: 300-1200 kg/hr (details see specification)

- Density: 26~45 kg/M3

Features

Sunwell Global is a leading manufacturer of XPS Foam Board Extrusion Lines and XPS Extruders, providing advanced solutions for high-quality foam insulation board production. Our tandem foam board extrusion lines are designed for efficient and consistent XPS foam board manufacturing, utilizing CO2 as a blowing agent for environmentally friendly production.

- High Production Capacity: With output capacities ranging from 250 kg/h to 1200 kg/h, our XPS Foam Board Extrusion Lines can produce board thicknesses from 20mm to 200mm and widths from 600mm to 1200mm, meeting diverse market demands.

- Automated Raw Material Handling: Up to 8 raw materials, including flame retardants and nucleating agents, are automatically loaded and blended for a uniform melt. This ensures consistent quality and optimal processing in the primary XPS extruder.

- Precision Blowing Agent Control: CO2, plasticizers, and/or HFC blowing agents are precisely metered using triple-head ATEX-compliant diaphragm pumps with mass flow measurement, ensuring stable foam density and superior board quality.

- Advanced Extrusion Technology: The secondary XPS extruder features a high mixing, low shear screw with a water-cooled bimetallic barrel and motorized valve control to minimize temperature variations. A static mixer and homogenizing tube ensure a uniform melt before entering the chrome-plated flat XPS die, which includes quick opening, fine-tune adjustment bolts, and Teflon guide shoes.

- Efficient Calibration and Cutting Systems: The board calibrator with temperature-controlled plates and robust haul-off system withstands CO2 expansion pressures and includes a fail-safe pneumatic quick opening mechanism. Travel conveyors allow for controlled cooling before edge milling and precise length cutting by a double-blade cross cutter designed for high-speed production.

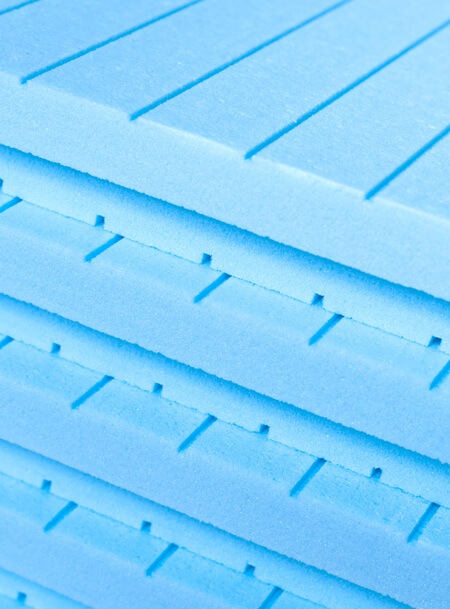

- Customizable Surface Finishing: Boards can be planed or grooved to meet specific market requirements. After further cooling, edges can be milled into flat surfaces, tongue and groove, or shiplap profiles.

- Fully Automated Stacking and Wrapping: Sunwell Global offers fully automatic board stacking and six-sided product wrapping, with optional features like product printing, soundproofing, and dust extraction for a complete production solution.

Applications

Insulation

Specifications

| MODEL | FEX120150XPS | FEX150200XPS | FEX180250XPS |

|---|---|---|---|

|

Thickness (mm)

|

20~100

|

25~160

|

30~200

|

|

Width (mm)

|

600; 900; 1,200

|

600; 900; 1,200

|

600; 900; 1,200

|

|

Length (mm)

|

1,000~3,000

|

1,000~3,000

|

1,000~3,000

|

|

Throughput (kg/h)

|

300~500

|

500~800

|

800~1,200

|

|

Density (kg/M3)

|

26~45

|

26~45

|

26~45

|

|

Extruder Type

|

Tandem

|

Tandem

|

Tandem

|

|

Screw Dia. (mm)

|

120 and 150

|

150 and 200

|

180 and 250

|

|

L/D

|

34/1 and 32/1

|

34/1 and 32/1

|

34/1 and 32/1

|

|

Blowing agent

|

Hydrocarbon, CO2, DME, HCFC, HFC

|

Hydrocarbon, CO2, DME, HCFC, HFC

|

Hydrocarbon, CO2, DME, HCFC, HFC

|

|

Drive System

|

SIEMENS AC drive with FLENDER gearbox

|

SIEMENS AC drive with FLENDER gearbox

|

SIEMENS AC drive with FLENDER gearbox

|

|

Barrel material

|

Bimetallic

|

Bimetallic

|

Bimetallic

|

|

Cooling system

|

Air cool for primary

Proportional motorized water cool for secondary |

Air cool for primary

Proportional motorized water cool for secondary |

Air cool for primary

Proportional motorized water cool for secondary |

|

Edge Profile

|

Shiplap, Tongue and Groove

|

Shiplap, Tongue and Groove

|

Shiplap, Tongue and Groove

|

|

Surface formation

|

Groove, Plane, Emboss

|

Groove, Plane, Emboss

|

Groove, Plane, Emboss

|

|

Floor Space (M)

|

80L x 15W x 6H

|

100L x 15W x 8H

|

120L x 20W x 8H

|