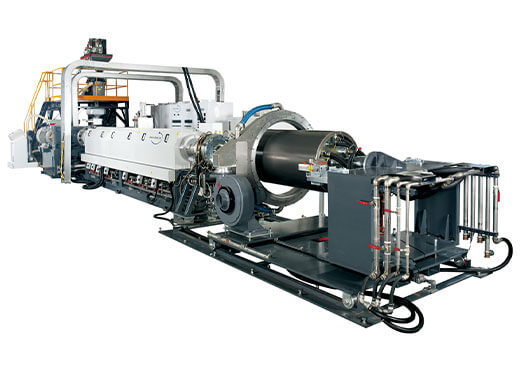

Foam Tube / Profile Extrusion Lines

Various EPE foam extrduer for insulation and protection packaging application.

- Material: LDPE

- Dimension: See Specification

- Output: 10-40 kg/hr (details see specification)

- Density: 22-30 kg/M3

Features

Sunwell Global is a leading provider of Foam Tube Extrusion and Profile Extrusion Line solutions, delivering high-performance systems for producing EPE foam pipes, rods, and profile products. Our extrusion lines are engineered for efficiency, durability, and consistent product quality, with output capacities ranging from 35 kg/h to 100 kg/h.

- Automated Material Handling: LDPE raw materials, along with GMS (Glycerin Mono Stearate) and talc, are automatically loaded and precisely blended to ensure a uniform melt. This process guarantees consistent product quality and optimal extrusion performance.

- Precision Gas Metering: Hydrocarbon gases are meticulously metered using high-pressure ATEX-compliant diaphragm pumps with mass flow measurement technology. This ensures stable foam density and high-quality finished products.

- Advanced Extrusion Technology: Our long single screw extruder incorporates precise process controls for plasticizing, mixing, and cooling. The finished products are extruded through a customizable die body with options for single to four ports, catering to various output capacities. The cooling and shaping process ensures consistent product dimensions and performance.

- Efficient Take-Off and Cutting Systems: Finished products are smoothly pulled by a caterpillar take-off system and accurately cut by a guillotine cutter. Products are then stacked or packaged for seamless downstream handling.

Sunwell Global's Foam Tube Extrusion and Profile Extrusion Lines are designed for industries requiring lightweight, durable, and high-performance foam products, providing reliable solutions for packaging, insulation, and protective applications.

Applications

Cushion & Protection

Specifications

| MODEL | FEX65 | FEX75 | FEX90 |

|---|---|---|---|

|

Material

|

LDPE

|

LDPE

|

LDPE

|

|

Sleeve internal dia.

|

12~75mm

|

12~100mm

|

12~120mm

|

|

Sleeve wall thickness

|

6; 10; 15; 20; 25; 30mm

|

6; 10; 15; 20; 25; 30mm

|

6; 10; 15; 20; 25; 30mm

|

|

Rod Dia.

|

/

|

Up to 75mm

|

Up to 90mm

|

|

Sheet Thickness

|

EPE: 0.8~ 6mm

|

EPE: 0.8~ 6mm

|

EPE: 0.8~ 6mm

|

|

Net mesh

|

Single or double

|

Single or double

|

/

|

|

Net Throughput

|

10~30 kg/hr

|

15~40 kg/hr

|

/

|

|

Sheet Width

|

1,000mm

|

1000~1,500mm

|

1000~1,500mm

|

|

Sheet Throughput

|

40 kg/hr

|

60 kg/hr

|

100 kg/hr

|

|

Density

|

22~30 kg/M3

|

22~30 kg/M3

|

22~30 kg/M3

|

|

Extruder Type

|

Long Single

|

Long Single

|

Long Single

|

|

Screw dia.

|

65mm

|

75mm

|

90mm

|

|

L/D

|

52/1

|

52/1

|

52/1

|

|

Blowing agent

|

Duplex or Triple Diaphragm Pump - Hydrocarbon

|

Duplex or Triple Diaphragm Pump - Hydrocarbon

|

Duplex or Triple Diaphragm Pump - Hydrocarbon

|

|

Drive System

|

SIEMENS AC drive with FLENDER gearbox or equivalent

|

SIEMENS AC drive with FLENDER gearbox or equivalent

|

SIEMENS AC drive with FLENDER gearbox or equivalent

|

|

Cooling system

|

Air cool combined with

Proportional motorized water cool |

Air cool combined with

Proportional motorized water cool |

Air cool combined with

Proportional motorized water cool |

|

Space requirement

|

10(L) x 3(W) x 4(H) m

|

12(L) x 3(W) x 4(H) m

|

15(L) x 3(W) x 4(H) m

|