High Speed Plastic Sheet Extrusion Lines

Energy-Efficient Rigid Sheet Extrusion Systems for High-Volume Production

- Material: PP, PET and other rigid sheet polymers

- Material Thickness: 0.3-1.2 mm (details see specification)

- Output: 900-1200 kg/hr (details see specification)

Features

Sunwell Global’s High-Speed Plastic Sheet

Extrusion Lines are engineered for manufacturers requiring stable high output,

precise sheet thickness control, and consistent downstream forming quality.

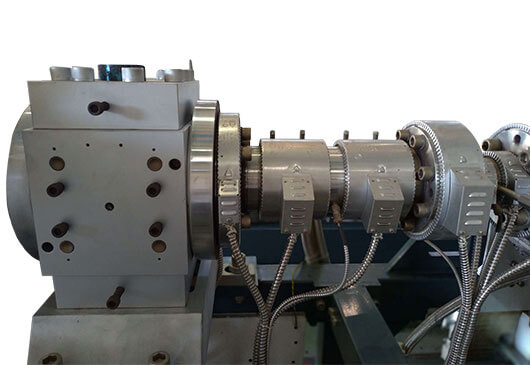

Featuring a hollow-shaft extruder design with a servo-driven motor, these

systems are optimized for energy efficiency and continuous high-speed operation

in large-volume production environments.

High-Output Extrusion Performance

Optimized screw geometry and precise temperature zoning enable high-capacity

production of up to 900 kg/hr for PP sheets and 1,200 kg/hr for PET sheets, making

the system ideal for continuous, high-volume manufacturing.

Accurate Sheet Thickness and Width

Control

Advanced flat die design and automatic thickness gauging systems ensure uniform

sheet thickness across the full width. Typical PET rigid sheet thickness ranges

from 0.15 to 1.2 mm, with line widths configurable from 1,200 to 1,600 mm,

depending on system configuration.

Stable Melt Flow for High-Speed

Operation

Engineered as a true high-performance extrusion system, the line maintains stable

melt pressure and efficient heat distribution, resulting in smooth sheet

surfaces and excellent performance in downstream thermoforming processes.

Multi-Material Processing Capability

The system supports a wide range of materials, including PP, HIPS, PET, PETG,

and PLA, enabling flexible production of food trays, lids, clamshells, blister

packaging, and biodegradable sheet products.

Integrated Cooling, Haul-Off, and

Sheeting/Winding Systems

The extrusion line integrates multi-roll cooling units, edge trimming,

servo-driven haul-off systems, and automatic sheeting or winding equipment, ensuring

minimal deformation, clean edges, and consistent sheet or roll quality.

PLC-Based Centralized Control System

A user-friendly PLC and touchscreen control interface manages temperature,

pressure, roll speed, and full line synchronization, supporting stable 24/7

operation and efficient process monitoring.

Applications

Plastic Cups / Tubs

Specifications

| PP Extrusion Specification | HSE 75mm PET/PP High Speed Extruder |

|---|---|

|

Material

|

PP; PET and Other Rigid Sheet Polymers

|

|

Power Consumption

|

IR Ceramic Efficient for Energy Saving;

~0.26kWh per kilo Power Consumption |

|

Layers

|

Single Extrusion Mono Layer or Co-extrusion Multi Layers

|

|

Production

|

Sheet Cut; Reel Wind; In-line with Thermoforming Machine

|

|

Thickness

|

PP: 0.3mm ~ 2mm; PET: 0.15mm~1.2mm

|

|

Width

|

500 ~ 1,600mm

|

|

Screw Dia

|

75mm

|

|

Maximum Screw Revolution

|

1000 RPM

|

|

Maximum Output

|

900 kg/h +/- 10% for PP; 1200 kg/h +/- 10% for PET

|

|

Line Speed

|

Up to 60M/Min.

|

|

Cooling Rolls Stack

|

Down stack or Up stack configuration

|

|

Cooling Rolls Stack.

|

Down stack or Up stack configuration

Vertical, Inclined or Horizontal, J Type, 3rd Roll Rotating type & Multiple Contact type for High Performance Requirements |

|

Slitting

|

Razor Blades, Rotating Blades

|

|

Winder

|

Fixed Shaft; Cantilever; Automatic Cut and changeover Turret Winder

|

|

Drive System

|

CMG Drive with Hallow Shaft Design for Screw Extraction from Back Side

|