IRD Crystallizing & Drying Handling System

Infrared drying system for plastic material or other in fast drying process.

- Application: 30% virgin + 30% regrind APET from in-house + 40% regrind APET from post consumed

- Buck density: virgin 0.75 g/cm3 + regrind 0.4 g/cm3

- Initial material moisture: virgin 0.4%; regrind 0.6%

- Handling capacity: 200~2,200 kgs/hr

- Process time: 12 min. (approximate)

Features

Sunwell Global’s IRD Crystallizing & Drying Handling System is designed for efficient processing of PET sheet, film extrusion, and injection molding, especially when using post-industrial or post-consumer regrind. This infrared drying system is also ideal for polyester fiber processors, offering faster performance compared to traditional drying methods.

- Direct Infrared Heat Application: Infrared rays generate molecular heat oscillation, heating particles from the inside out, effectively reducing moisture from over 4,000 ppm to less than 50 ppm in minutes.

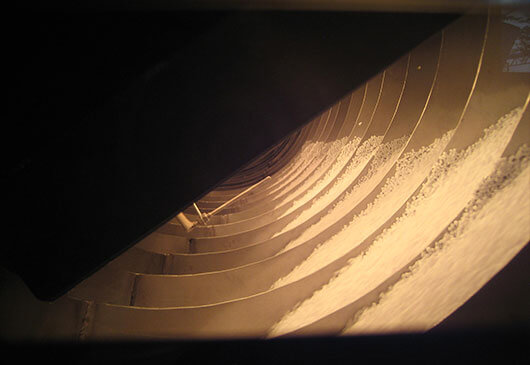

- Rotary Drum Design: The infrared rotary dryer features a stainless steel drum with an internal helix, ensuring all surfaces of the materials are evenly exposed to infrared rays for consistent drying and crystallizing.

- Precise Control: Adjustable drum speed and infrared power provide precise temperature and exposure time management, preserving the intrinsic viscosity (IV) properties of PET materials during processing.

Benefits for PET Processing

This infrared drying system offers continuous processing, drastically reducing drying times from hours to minutes. It is ideal for PET sheet extrusion, film extrusion, and injection molding, ensuring high efficiency in drying and crystallizing PET flakes while maintaining material integrity.

Applications

Specifications

| MODEL | IRD150-270 | IRD180-270 | IRD180-360 | IRD180-450 |

|---|---|---|---|---|

|

Drum size (Dia. x L mm) |

1500 x 2700 | 1800 x 2700 | 1800 x 3600 | 1800 x 4500 |

|

Feeder size (Dia. x L mm) |

139 x 650 | 139 x 650 | 139 x 650 | 139 x 650 |

|

Output capacity (kgs/h) |

~500 | ~800 | ~1200 | ~1500 |

| Temp. control zones | 3 | 3 | 4 | 5 |

| Heater banks | 3 | 3 | 4 | 5 |

| Infrared lamps power (kW) | 135 | 135 | 180 | 225 |

|

Feeding power (kW) |

0.75 | 0.75 | 0.75 | 0.75 |

|

Drum turning power (kw) |

0.75 x 2 | 0.75 x 2 | 0.75 x 2 | 0.75 x 2 |

|

Cooling Blower (kw) |

2.2 | 3.7 | 3.7 | 5.5 |

|

Extraction fan (kW) |

2.2 | 3.7 | 3.7 | 5.5 |