MS Series Thermoforming Machine

Application of thermoforming machine for high speed shallow draw mass production. Suitable for fast food packaging.

- Forming Method: Pressure Forming

- Maximum Sheet Width: 900-1460 mm (details see specification)

- Maximum Dry Cycle Speed: 40 cycle/min (details see specification)

Features

Sunwell Global's MS Series is a high-performance Shallow Draw Thermoforming Machine, specifically designed for producing lightweight and shallow-formed foam products with advanced technology and exceptional efficiency. This machine offers precise control and versatile processing capabilities for various materials, including Polystyrene (PS), Polypropylene (PP), and Polyethylene (PE).

- Advanced Shallow Draw Thermoforming Technology: The MS Series features a continuous separate station system with two stages: forming and independent trimming. This setup ensures efficient production of shallow containers and trays with clean, precise cuts. Integrated in-line scrap granulation minimizes waste and labor, enhancing production efficiency.

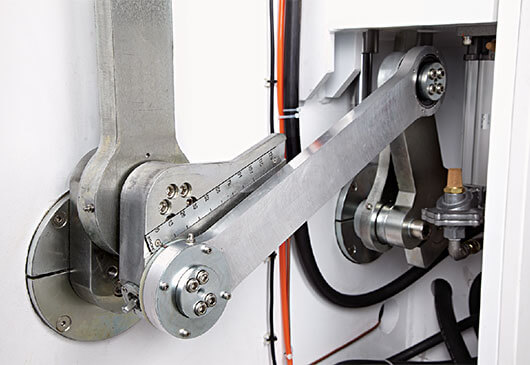

- Servo-Driven Precision Control: Powered by dual-axis servo motors connected to mechanical toggles, the MS Series allows independent control of the top and bottom platens, ensuring accurate and consistent shallow forming. This makes it ideal for producing disposable food packaging and foam products.

- Optimized Heating System: The heat tunnel is equipped with high-quality ceramic heating elements and multi-zone temperature controls to guarantee uniform heating of the sheet. The servo-driven chain feed index ensures precise material positioning and synchronization with the program interface.

- Efficient Trimming Capabilities: The horizontal (or optional vertical) trim press features servo-driven moving platens with an extended stroke for accurate pre-punching and trimming of shallow-formed products. This ensures clean edges and high product quality.

- Automated Handling and Scrap Management: Additional servo actions manage product indexing and ejection, accurately placing finished products onto the packing table for streamlined packaging. Post-trimming scrap is automatically fed into an in-line granulator, reducing space requirements and labor costs.

Applications

Plates / Dishes

Styrofoam Food Packaging

Poultry & Meat Trays

Specifications

| MODEL | MS900 | MS1200 | MS1370 | MS1460 |

|---|---|---|---|---|

|

Configuration

|

Forming front, post trim with scrap granulation inline

|

Forming front, post trim with scrap granulation inline

|

Forming front, post trim with scrap granulation inline

|

Forming front, post trim with scrap granulation inline

|

|

Application

|

Foam products or thin gauge shallow products

|

Foam products or thin gauge shallow products

|

Foam products or thin gauge shallow products

|

Foam products or thin gauge shallow products

|

|

Forming method

|

Vacuum and slight pressure forming

|

Vacuum and slight pressure forming

|

Vacuum and slight pressure forming

|

Vacuum and slight pressure forming

|

|

Forming direction

|

Either above or below sheet forming

|

Either Above or Below Sheet Forming

|

Either Above or Below Sheet Forming

|

Either above or below sheet forming

|

|

Maximum Sheet Width

|

900 mm

|

1,200 mm

|

1,370 mm

|

1,460mm

|

|

Mold Size

(mm) |

Max. 850 x 1,000

Min. 600 x 760 |

Max. 1,150 x 1,200

Min. 850 x 800 |

Max. 1,320 x 1,350

Min. 1,000 x 1,000 |

Max. 1,400 x 1,500

Min. 1,000 x 1,000 |

|

Max. Depth of Draw

|

100 mm

|

100 mm

|

100 mm

|

100 mm

|

|

Forming Tonnage (ton)

|

80 tons

|

80 tons

|

80 tons

|

80 tons

|

|

Shut-height (mm)

|

Top = 150

Bottom = 150 |

Top = 150

Bottom = 150 |

Top = 150

Bottom = 150 |

Top = 150

Bottom = 150 |

|

Platen Travel

|

Top = 180

Bottom = 180 |

Top = 180

Bottom = 180 |

Top = 180

Bottom = 180 |

Top = 180

Bottom = 180 |

|

Max. Dry Cycle Speed

|

50 cycles / Min.

|

50 cycles / Min.

|

50 cycles / Min.

|

50 cycles / Min.

|

|

Platen Drive

|

AC Servo driven;

Toggle linkage |

AC Servo driven;

Toggle linkage |

AC Servo driven;

Toggle linkage |

AC Servo driven;

Toggle linkage |

|

Sheet Index

|

AC Servo Driven Chain Feed

|

AC Servo Driven Chain Feed

|

AC Servo Driven Chain Feed

|

AC Servo Driven Chain Feed

|

|

Heat Tunnel Length

|

4,000 mm

|

5,000 mm

|

5,600 mm

|

6,000 mm

|

|

Heating Elements

|

Ceramic

|

Ceramic

|

Ceramic

|

Ceramic

|

|

In line with Trim Press

|

Horizontal Trim Press or Alternative

|

Horizontal Trim Press or Alternative

|

Horizontal Trim Press or Alternative

|

Horizontal Trim Press or Alternative

|

|

Trim Press Drive

|

AC Servo driven; Crank reciprocatedrun

|

AC Servo driven; Crank reciprocatedrun

|

AC Servo driven; Crank reciprocatedrun

|

AC Servo driven; Crank reciprocatedrun

|

|

Trimming Max. Speed

|

160 cpm

|

160 cpm

|

160 cpm

|

160 cpm

|

|

Trimming Tonnage

|

20 tons

|

20 tons

|

20 tons

|

20 tons

|

|

Control System

|

YASKAWA 2200

|

YASKAWA 2200

|

YASKAWA 2200

|

YASKAWA 2200

|

|

Floor Space (M)

|

20L x 4W x 4H M

|

22L x 4W x 4H M

|

23L x 4.5W x 4H M

|

24L x 5W x 4H M

|

|

Machine Weight

|

12,000 kg

|

14,000 kg

|

16,000 kg

|

18,000 kg

|