高速型塑膠片材押出機

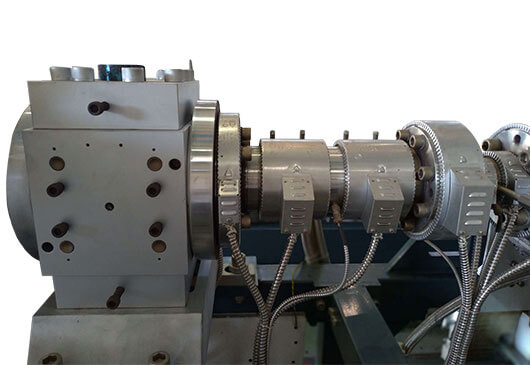

膠片押出機 (中空軸設計,伺服馬達及載力最佳化)

- 材質:PP,PET和其他剛性片狀聚合物

- 材料厚度:0.3-1.2毫米 (詳細信息請參閱規格)

- 產量:900-1200 kg / hr (詳細信息請參閱規格)

特色

昇威國際HSE高速押出機,高速生產塑膠片材:PP片材每小時生產900kg; PET片材每小時生產1200kg。馬達控制系統扭矩為1,000rpm空心軸設計,螺桿可從尾端取出。

常規的加熱元件為紅外線陶瓷加熱片並搭配鼓風機。高速押出機經過多次修正與改善後,性能更為穩定。與常規的押出機系統比較,更能提高節能、高產量、平整度、表面光滑、內部應力減少及高透明度。

應用範圍

塑膠杯

規格

| PP Extrusion Specification | HSE 75mm PET/PP High Speed Extruder |

|---|---|

|

Material

|

PP; PET and Other Rigid Sheet Polymers

|

|

Power Consumption

|

IR Ceramic Efficient for Energy Saving;

~0.26kWh per kilo Power Consumption |

|

Layers

|

Single Extrusion Mono Layer or Co-extrusion Multi Layers

|

|

Production

|

Sheet Cut; Reel Wind; In-line with Thermoforming Machine

|

|

Thickness

|

PP: 0.3mm ~ 2mm; PET: 0.15mm~1.2mm

|

|

Width

|

500 ~ 1,600mm

|

|

Screw Dia

|

75mm

|

|

Maximum Screw Revolution

|

1000 RPM

|

|

Maximum Output

|

900 kg/h +/- 10% for PP; 1200 kg/h +/- 10% for PET

|

|

Line Speed

|

Up to 60M/Min.

|

|

Cooling Rolls Stack

|

Down stack or Up stack configuration

|

|

Cooling Rolls Stack.

|

Down stack or Up stack configuration

Vertical, Inclined or Horizontal, J Type, 3rd Roll Rotating type & Multiple Contact type for High Performance Requirements |

|

Slitting

|

Razor Blades, Rotating Blades

|

|

Winder

|

Fixed Shaft; Cantilever; Automatic Cut and changeover Turret Winder

|

|

Drive System

|

CMG Drive with Hallow Shaft Design for Screw Extraction from Back Side

|